16.10.2025

By Marketing Team

As UAVs (unmanned aerial vehicles) evolve from hobbyist drones into critical tools for industrial inspection, defence reconnaissance, precision agriculture, and emergency logistics, their most significant technical bottleneck remains unchanged: energy storage. Whether the goal is longer flight times, higher payload capacities, or extended mission ranges, advancements in battery technology are the decisive factor.

While lithium-ion batteries have propelled UAV capabilities dramatically over the past decade, their practical energy density is now brushing against physical and chemical limits. This is where lithium-sulfur batteries come into the spotlight—offering the promise of a fundamentally different chemistry with radically improved energy storage potential.

What Makes Lithium-Sulfur Batteries Different?

With theoretical specific energies reaching 500 Wh/kg, lithium–sulfur batteries are drawing global attention as a next-generation solution, offering a significant leap in energy density compared to leading lithium-ion cells. For UAVs, where performance hinges on the delicate balance between weight and endurance, this advancement could be revolutionary. It enables longer missions, greater payloads, and a fundamental redefinition of operational limits.

Here’s why the chemistry is so attractive:

But the advantages of lithium-sulfur batteries also come with significant engineering hurdles that must be resolved before they become the new standard for UAV power.

The Challenges Slowing Adoption

Despite the excitement, lithium-sulfur batteries still struggle with cycle life and durability—two crucial factors for commercial UAV operators who need reliability over hundreds or thousands of recharge cycles.

One major issue is the polysulfide shuttle effect. During discharge, sulfur reacts to form lithium polysulfides, which can dissolve in the electrolyte and migrate to the anode, causing unwanted side reactions. This leads to rapid capacity fade and poor coulombic efficiency.

Lithium-sulfur electrodes undergo substantial volume changes (up to 80%) during charge and discharge. Over time, this expansion and contraction can break down the electrode structure, reducing capacity and shortening lifespan.

Sulfur itself is not a good conductor of electricity, so it requires careful design of the cathode architecture to ensure efficient charge transfer.

Why Lithium-Sulfur Still Matters for UAVs

For UAV applications, these challenges are serious but not deal-breakers. That’s because UAVs represent an energy use case where lightweight, high-energy bursts are often more valuable than extreme cycle longevity.

Battery researchers and manufacturers are aggressively pursuing solutions to the main pain points of lithium-sulfur systems. Some promising developments include:

These improvements are rapidly moving lithium-sulfur from theoretical promise toward commercial deployment, especially in niche applications where weight is critical.

These improvements are rapidly moving lithium-sulfur from theoretical promise toward commercial deployment, especially in niche applications where weight is critical.

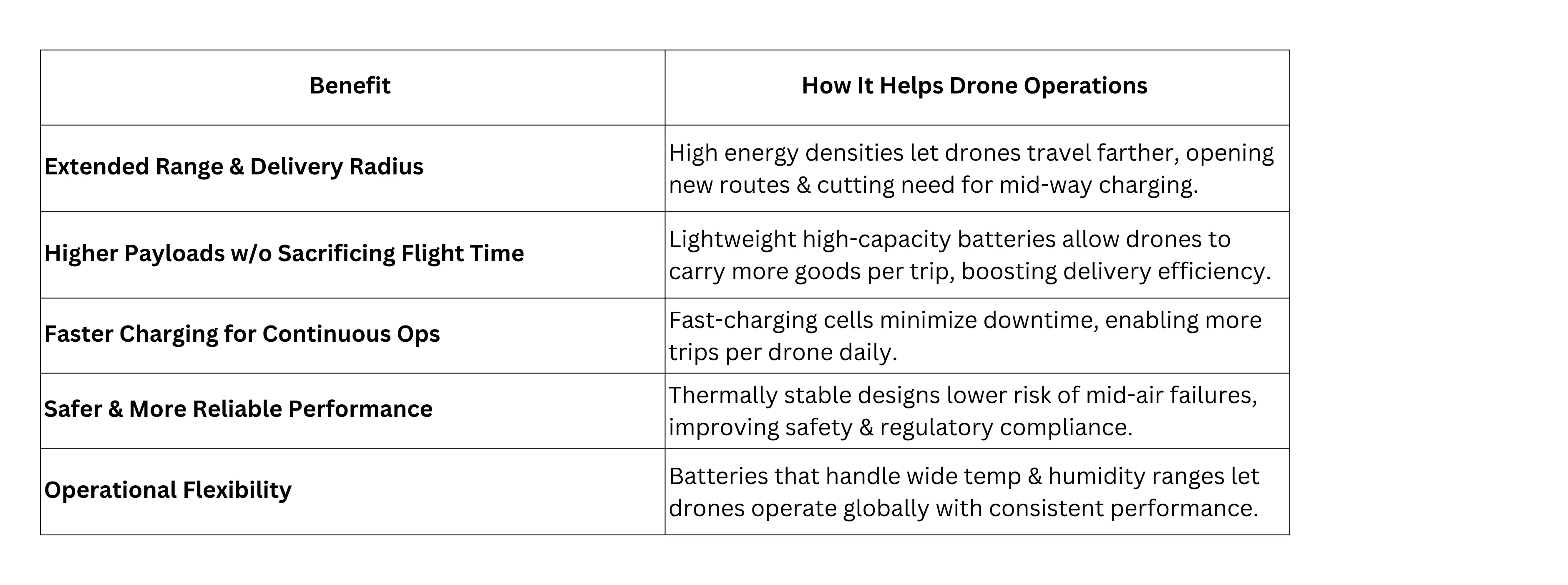

When these advances reach scalable production, the impact on UAV design will be profound:

Doubling the energy density directly translates to doubling the endurance, or alternatively allows designers to halve the weight of the battery and allocate more mass to sensors, cameras, or cargo.

With lighter power sources, UAVs can be made more compact or achieve the same performance with smaller propulsion systems.

Longer loiter times for border patrol, multi-hour crop surveys without landing, or cross-river cargo deliveries in remote areas all become practical.

At Trydan Tech, we believe energy storage is the foundation of next-generation UAV performance. That is why we are advancing lithium–sulfur technology to deliver the high energy density needed for mission-critical and high-power aerial applications.

Our work is centered on developing high-performance lithium–sulfur cells that maximize endurance and payload capacity while maintaining the reliability and safety UAV operators demand. From long-range surveillance drones to heavy-lift industrial UAVs and emerging eVTOL platforms, our cells are engineered to meet the most demanding flight profiles.

Lithium–sulfur batteries are no longer just a laboratory concept. They represent a viable path toward unlocking new levels of performance in UAVs and other lightweight aerial systems. As ongoing research continues to overcome long-standing challenges such as limited cycle life and mechanical degradation, these batteries are rapidly advancing from experimental stages to pilot programs and soon, widespread deployment.

The future of UAV endurance and payload capability is poised for a significant leap forward as lithium–sulfur technology matures.

We use cookies to enhance your browsing experience, analyze site traffic, and personalize content. By continuing to use our site, you consent to our use of cookies. Learn more