16.10.2025

By Marketing Team

In the rapidly evolving landscape of unmanned aerial vehicles (UAVs), energy is everything. Whether used for delivery, surveillance, agriculture or inspection, drones rely heavily on battery performance to complete their missions. As drone applications grow more complex, the demand for powerful, lightweight and reliable batteries is intensifying, and battery cell manufacturers are at the center of this transformation.

Traditionally, most drone battery supply has come from global markets, particularly China and South Korea. But the tide is shifting. India is emerging as a serious player in energy technology, driven by innovation across its domestic manufacturing ecosystem. This blog explores the rise of drone battery manufacturing in India, what battery makers need to know to stay ahead, and how to align with the needs of OEMs in a fast-changing supply chain landscape.

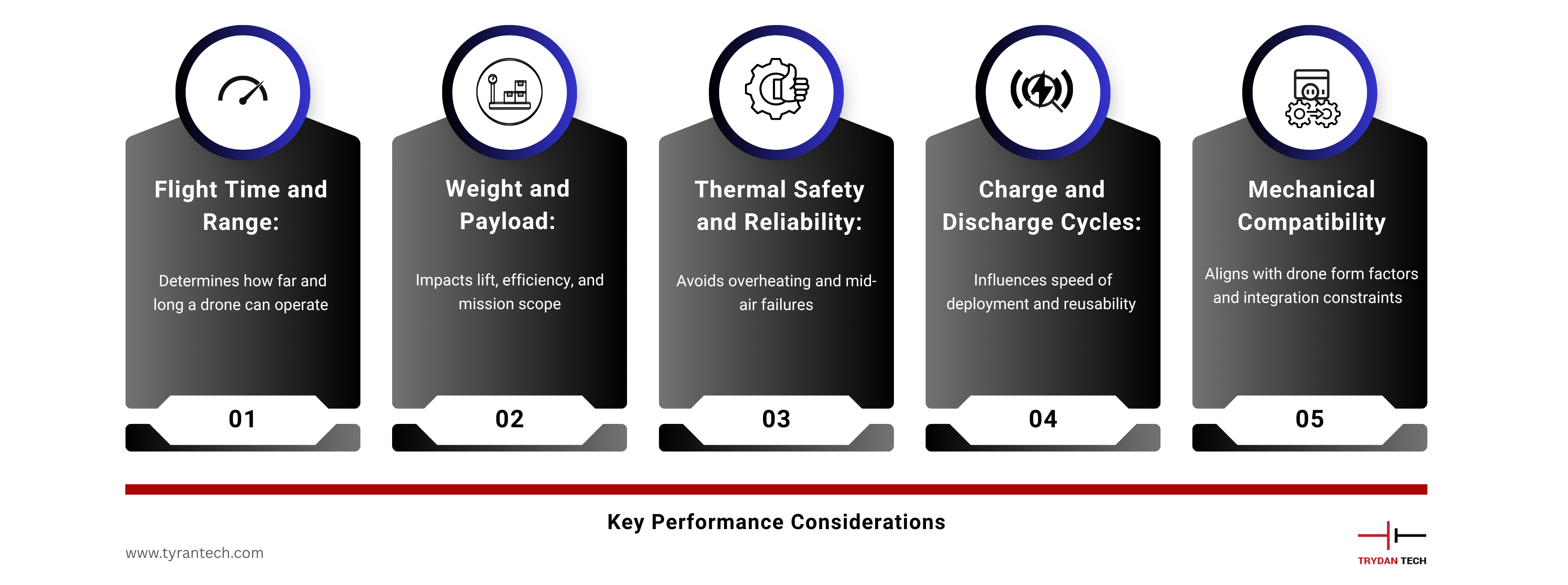

In any drone system, the battery is far more than just a power source. It is the operational core. From flight time and payload capacity to turnaround cycles and safety, battery performance influences every critical metric.

For battery cell manufacturers, this means understanding not just chemistry and design, but also the practical mission requirements of drone OEMs. The ability to engineer tailored energy solutions can make or break the success of a drone product in the market.

Key performance considerations include:

Manufacturers that deliver across these parameters will be best positioned to serve the growing UAV sector.

India’s battery ecosystem has undergone a major transformation in the last five years. Once dependent on imported cells, the country now boasts a growing network of research labs, deep-tech startups, pilot-scale cell units and advanced pack integrators. This evolution is being fueled by both government support and rising demand across the drone and EV industries.

Key drivers of this momentum include:

For battery cell manufacturers, this ecosystem presents a strong platform to scale, innovate and serve global markets from India.

To meet the demands of drone OEMs and stay competitive, battery makers in India must focus on five key areas.

Different drone missions demand different chemistries. Manufacturers must understand and recommend the right chemistry mix based on the application.

Providing consultative support to OEMs during the selection or customization process is now a competitive differentiator.

Drones require fast energy bursts during takeoff, landing and dynamic maneuvers. Battery packs must support:

Manufacturers need to validate these capabilities through rigorous real-world testing and simulation.

Drones are aerodynamically optimized, and every gram impacts flight efficiency. Battery manufacturers must prioritize:

Reducing battery weight directly contributes to longer flight times, better maneuverability, and increased payload capacity, all critical for competitive drone performance.

Time to market is critical in the UAV industry. battery cell manufacturers must provide:

This co-engineering approach helps align energy systems with drone performance goals more precisely.

Compliance is now a baseline requirement, not an afterthought. Manufacturers must ensure:

Certifications also unlock access to global OEMs and defense procurement channels.

Indian battery cell manufacturers are uniquely positioned to offer a blend of cost, speed, and innovation. Here's why global drone OEMs are increasingly partnering with India-based suppliers:

Battery makers who capitalize on these advantages will be able to meet both domestic and global demand with agility.

At Trydan Tech, We engineer energy solutions for mission-critical drone operations. With facilities in both India and the US, we develop advanced energy storage systems tailored for logistics, surveillance, agriculture and industrial UAVs.

What sets us apart:

For battery cell manufacturers exploring co-development or OEMs seeking performance-ready solutions, Trydan Tech brings the expertise and execution to meet global standards.

As the drone revolution continues to scale across sectors, energy systems are becoming the strategic foundation of performance, safety and commercial viability. Battery cell manufacturers in India can lead this change by aligning with global quality standards, innovating in cell design and chemistry, and responding quickly to market-specific needs.

India is no longer just assembling batteries. It is building a global identity in drone energy innovation. With the right capabilities and partnerships, battery makers can define the next phase of UAV performance, powered from India.

We use cookies to enhance your browsing experience, analyze site traffic, and personalize content. By continuing to use our site, you consent to our use of cookies. Learn more