18.09.2025

By Marketing Team

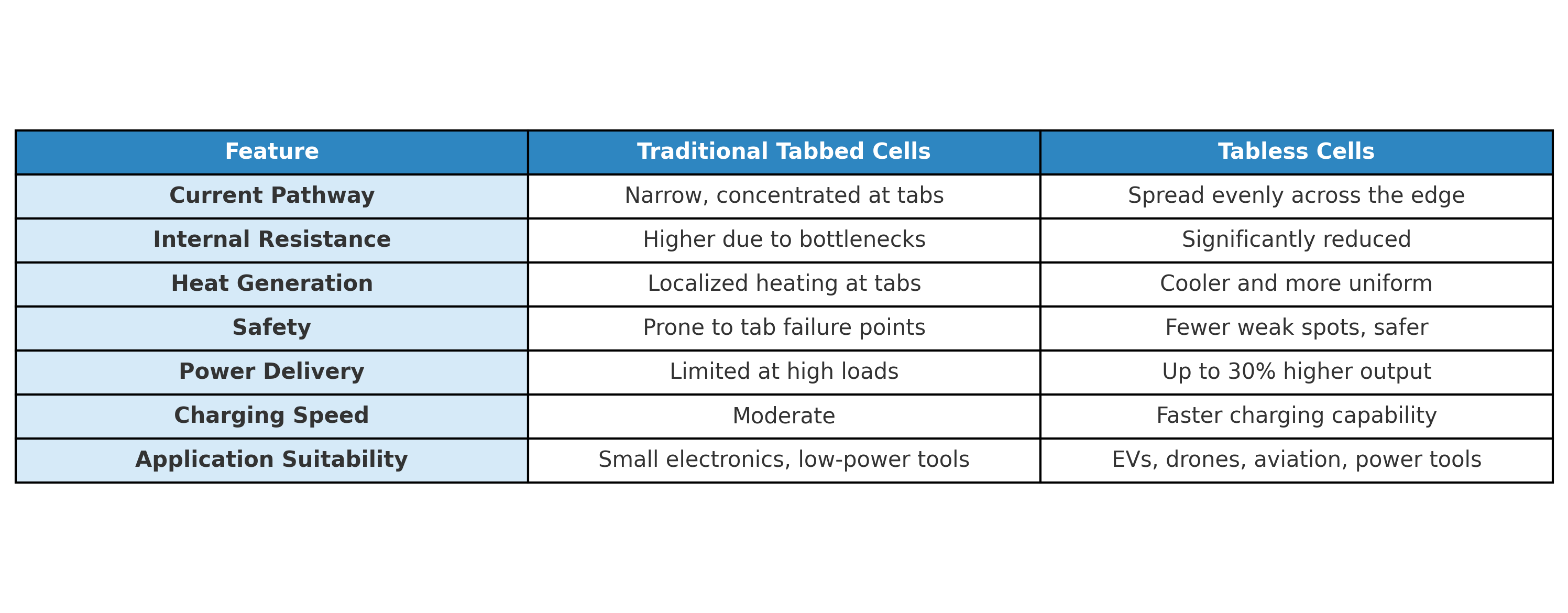

Lithium-ion batteries have powered the modern age, from smartphones to electric vehicles (EVs). Yet, even the most advanced traditional cells face challenges such as heat generation, limited power delivery, and efficiency loss under high demand. In recent years, tabless battery design has emerged as a transformative solution. Unlike conventional tabbed cells, tabless batteries reduce resistance, manage heat more effectively, and unlock higher performance for demanding applications such as EVs, drones, aviation, and industrial tools.

This blog compares traditional tabbed cells with tabless cells, exploring their differences, benefits, and why innovations like the Trydan 5000 T series are setting new industry standards.

In traditional cylindrical cells such as 18650 or 21700 formats, current flows through tabs—small strips of metal welded to the electrodes. These tabs serve as the pathways for electrical current between the internal electrode layers and the external terminals.

While proven, this design becomes limiting in high-power and high-capacity applications. As the current demand increases, tabs act as bottlenecks, leading to higher resistance, increased heat, and reduced efficiency.

Tabless technology eliminates the need for separate current-carrying tabs. Instead, the entire edge of the electrode acts as a continuous current collector.

This simple yet revolutionary design shift enables faster charging, longer runtimes, and greater reliability, making tabless cells the go-to choice for the next generation of energy storage.

As industries push for higher efficiency and sustainability, battery performance becomes a competitive advantage. Tabless cells deliver tangible improvements in:

The Trydan 5000 T Series exemplifies the real-world advantages of tabless technology. Designed for industries that demand both power and efficiency, it brings together performance, safety, and reliability.

By addressing the limitations of traditional cells, the Trydan 5000 T Series positions itself as a future-proof energy solution—one that aligns with the performance demands of cutting-edge industries while keeping sustainability in focus.

The shift from traditional tabbed cells to tabless designs represents a critical evolution in battery technology. Tabless cells overcome the bottlenecks of conventional designs, delivering superior thermal management, safety, and performance.

We use cookies to enhance your browsing experience, analyze site traffic, and personalize content. By continuing to use our site, you consent to our use of cookies. Learn more