25.09.2025

By Marketing Team

The demand for higher-performing lithium-ion batteries has never been greater, driven by the growth of electric vehicles, renewable energy storage, and advanced next-gen applications. As traditional cylindrical cells such as 18650 and 21700 reach their engineering limits, the industry is innovating with new designs that reduce inefficiencies and improve scalability. Among these innovations, tabless battery cells stand out as a breakthrough in performance, safety, and manufacturability.

In this article, we’ll explore what tabless cells are, why they matter, and how their technical design addresses the limitations of conventional tabbed cells.

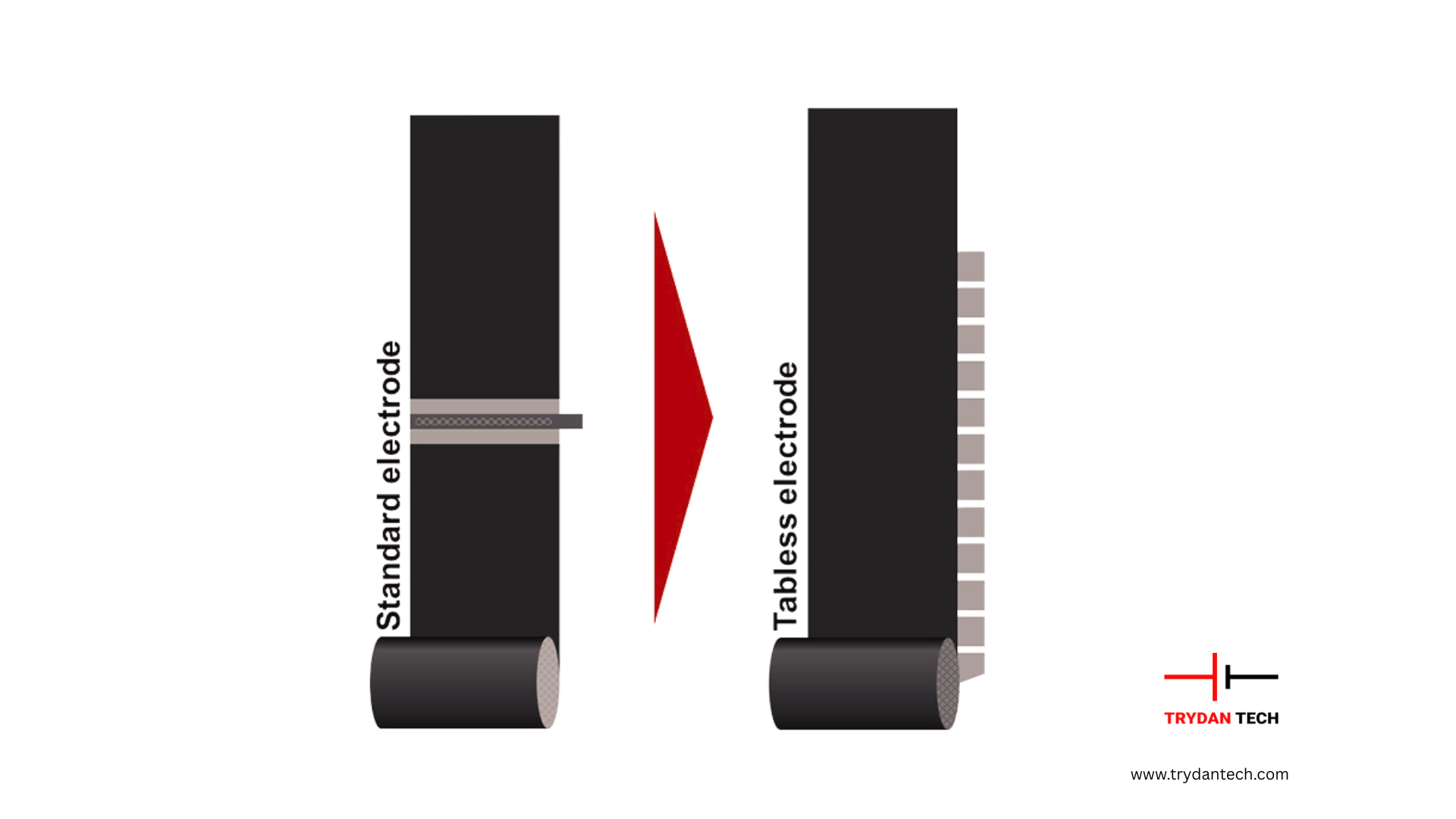

A cylindrical lithium-ion cell is essentially a jelly roll – a spirally wound structure of anode, cathode, and separator layers. In conventional cells, current is collected through tabs: strips of conductive metal (nickel, copper, or aluminum) welded at specific points on the electrodes.

These tabs act like “doors” through which current enters and exits the electrode. However, because tabs are discrete and localized, the current flow must travel across the entire electrode sheet toward a few exit points. This creates longer internal pathways, higher resistance, and uneven current distribution.

In a tabless cell, the electrodes are not restricted to just a few tabs. Instead, the current is collected continuousl along the edges of the jelly roll. This is done by notching or extending the electrode foils so that the entire edge is in direct contact with a current collector plate or the cell housing.

In simple terms:

This drastically reduces the bottlenecks inside the cell.

1)Reduced Internal Resistance

2)Better Thermal Management

3)Higher Power Capability

4)Scalability in Larger Formats

The jelly roll’s geometry plays a critical role in performance:

Resistance analysis:

Interestingly, tabless design is not primarily about increasing energy density—it’s about improving power delivery and thermal stability.

At Trydan Tech, the 5000T series represents a practical application of tabless cylindrical architecture. This cell combines high capacity with high power delivery by leveraging continuous current collection along the electrode edges. The result is lower resistance, better thermal stability, and higher sustained performance compared to traditional tabbed cells.

Applications such as drones, e-mobility, and high-drain industrial equipment benefit directly from this design, gaining extended runtimes, faster charging, and reliable high-power bursts without compromising safety. With the 5000T series, tabless technology is no longer a concept—it’s a reality powering next-generation solutions.

Tabless cells represent a fundamental shift in cylindrical battery design. By eliminating discrete tabs and enabling continuous current collection, they reduce resistance, improve thermal management, and unlock higher performance at larger scales.

While not all designs on the market today are fully tabless, the industry is clearly moving in this direction. For applications requiring fast charging, high power output, and safe thermal behavior, tabless cells will be the foundation of next-generation battery applications.

As research advances and manufacturing matures, we can expect to see true fully tabless designs that redefine performance standards for the future of energy and electrification.

We use cookies to enhance your browsing experience, analyze site traffic, and personalize content. By continuing to use our site, you consent to our use of cookies. Learn more